4

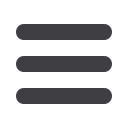

HLA Series Hazardous Location Fan Forced Unit Heater

FAN-FORCED SUSPENDED UNIT HEATERS 3-25 KW FOR T-3B CLASS I, GROUP C & D,

DIVISION 1 & 2 AND CLASS II, GROUPS E, F & G, DIVISIONS 1 & 2.

Shown with optional pilot

light and disconnect switch

Heat Exchanger and Elements:

Heavy walled, painted carbon steel with aluminum fins liquid heat exchanger, liquid filled with three-immersion type copper

sheathed elements. The elements shall have the highest quality nickel-chromium resistance wire encased in a magnesium oxide

dielectric and be hermetically sealed into the heat exchanger core. The heat transfer fluid is Ethylene-glycol solution for operation

to -49 degrees F (– 45 degrees C). Stainless steel and aluminum pressure relief valve for overpressure.

Thermal Cutout High Limit Protection and Optional Pilot Light:

The capillary type manual reset thermal cutout shall be rated for 6000 cycles of service and mounted in the liquid filled heat

exchanger. An optional pilot light to indicate manual reset tripped, if safe operating temperatures are exceeded, is located on

control enclosure.

Motor:

The motor shall be a permanent split capacitor type, permanently lubricated, ball bearing type. The motor shall be rated for

hazardous location and operate at rated voltage of heater, 60 Hz, 1725 RPM.

Control Enclosure:

All controls shall be factory installed and wired in a hazardous location enclosure. Contactors and back-up contactors are heavy

duty type and break all ungrounded conductors and be rated for 100,000 cycles at full load. Standard 24-Volt control circuit shall

be supplied by internal class II transformer. An optional factory wired integral thermostat or standard terminal block for field

wiring to optional remote wall thermostat are wired in control panel. No fan delay relay.

Disconnect Switch:

Factory mounted and wired hazardous location disconnect switch is available as optional accessory.

Cabinet With Adjustable Louvers:

The Cabinet shall be 14 gauge, cold rolled steel with powder coated epoxy finish. Plated fan guards with less than 1/4 inch

spacing to cover motor and fan shall conform to OSHA Requirements.

Note:

Before selecting a hazardous location electric heater refer to Article 500 or other applicable standard referenced in the National

Electric Code.

Product Specifications

• Designed for rugged industrial applications in hazardous locations

where the possibility of explosion or fire exists due to the presence of

certain flammable gases, vapors, powdered metals or dust.

• Permanently sealed, liquid to air, finned tube heat exchanger core.

• Ethylene Glycol to water mixture used as a heat transfer fluid in the

heater core, providing -45° C. (-49° F) freeze damage protection.

• High-performance electric motor driven fan blows air across finned

tubes to effect uniform heat transfer and area heat distribution.

• Manual Reset capillary type limit provides high temperature regulation

and is rated for 6,000 cycles of service.

• Stainless steel and aluminum pressure relief valve for overpressure.

• A back-up contactor is included for additional protection.

• 14 gauge steel cabinet powder coated epoxy paint finish contains heater

core, motor, and fan assembly.

• Narrow gap safety fan guard shields all moving parts.

• Adjustable louvers allow directional control of air.

• Copper conductor wires enclosed in rigid metal conduits carry all

electrical power.

• Box lugs furnished for field connections within approved enclosure.

• Made in U.S.A.

Liquid-to-air heat exchanger

Optional built-in thermostat

Hazardous Location Rated Motor