21

2600 Series Downflow Unit Heater

Standard Models

Product Specifications

SPECIFICATIONS:

The contractor shall furnish and install the 2600 Series electric vertical discharge unit heaters of the size, capacity and

voltage specified. Heaters shall be installed according to the manufacturer’s recommendations and applicable national and local codes.

ELEMENTS:

Elements shall consist of Nickel Chromium alloy resistance wire embedded and completely surrounded in Magnesium Oxide,

enclosed and swagged into corrosion resistant sheaths. Corrosion resistant steel fins shall be permanently attached to the sheaths to provide

maximum heat transfer to the air stream.

MOTORS:

Motors shall be single phase, resilient mounted, totally enclosed, industrial rated with an automatic reset thermal overload protective

device. Motors on heaters up to 20 KW capacity shall be permanently lubricated shaded pole type. Over 20 KW, motors shall be permanent split

capacitor type. Motors shall be mounted out of the main air stream in such a manner as to allow ambient air to be drawn over the motor to reduce

motor temperature. Motor shall be separately removable from beneath the heater without removing the entire heater from mounting bracket.

FAN BLADES:

Fan blades shall be heavy-duty individually balanced axial flow type. Fan speed shall not exceed 1570 RPM.

THERMALOVERLOAD PROTECTION:

All heaters shall be equipped with a manual reset thermal cutout which disconnects elements and

motor in the event normal operating temperatures are exceeded.

WIRING:

Heaters shall be designed for a single supply circuit with elements, motor and control circuits subdivided and fused to conform with

the latest National Electric Code and OSHA requirements. All three phase heaters shall have balanced phases.

CONTROLS:

Heaters shall be controlled by a low voltage wall mounted thermostat. All heaters 25 KW and larger shall be wired for 2 stage

operation. 5 KW through 20 KW units are single stage. All heaters shall be equipped with a fan safety device that causes fan to operate after

elements are de-energized to purge unit of residual heat.

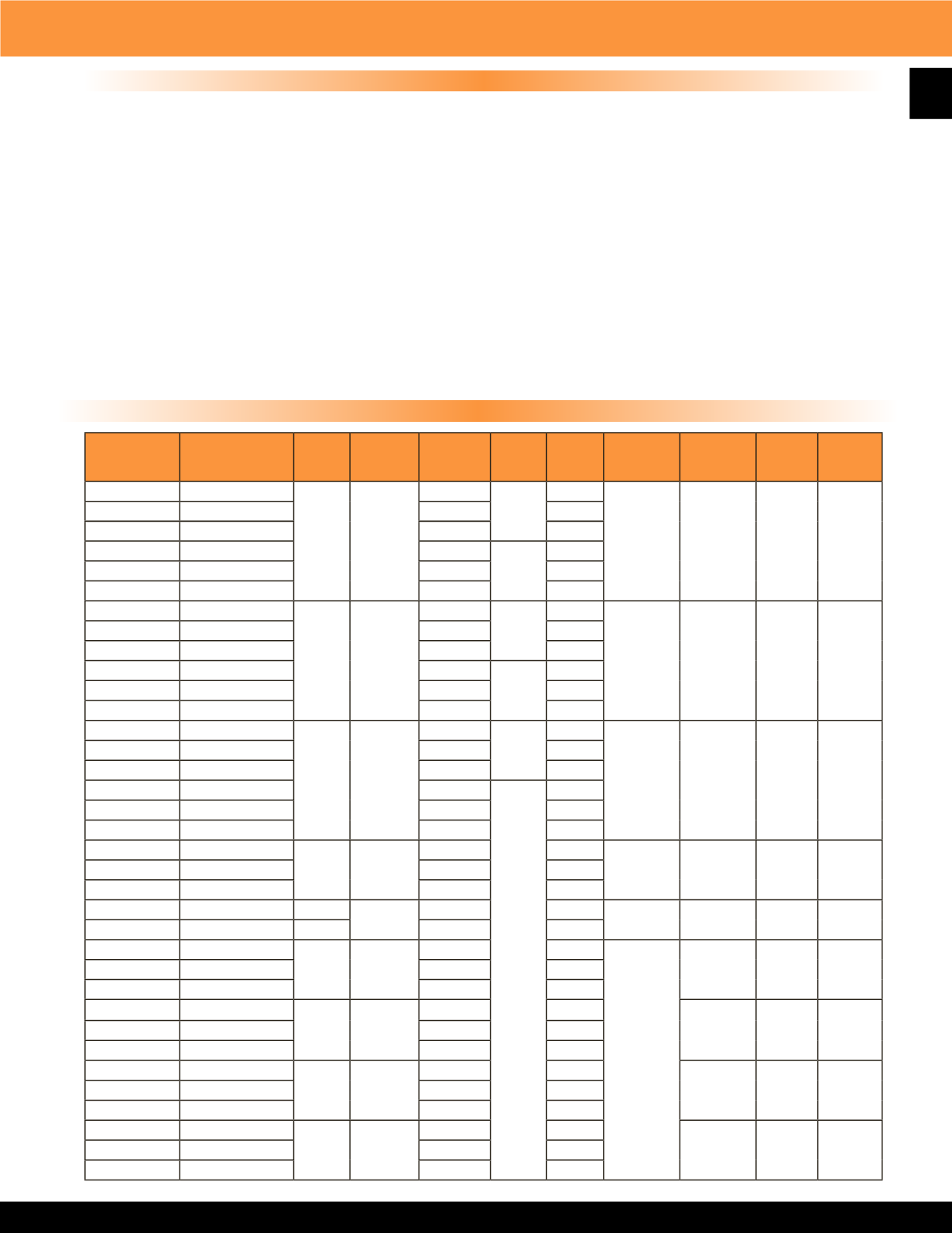

MFG

CATALOG

NUMBER

MFG

MODEL

NUMBER

KW BTU’s

VOLTS PH

AMPS CONTROL

VOLTS

TEMP

RISE

O

F CFM WT

(LBS)

07157502

F1F2605CA1

5

17065

208

1

24.03

24

34

490

75

07157602

H1H2605CA1

240

20.83

07157702

G1G2605CA1

277

18.05

07157802

F3F2605CA1

208

3

13.89

07157902

H3H2605CA1

240

12.04

07158002

P3P2605CA1

480

6.02

07158202

F1F2607CA1

7.5

25598

208

1

36.05

24

45

560

75

07158302

H1H2607CA1

240

31.25

07158402

G1G2607CA1

277

27.07

07158502

F3F2607CA1

208

3

20.84

07158602

H3H2607CA1

240

18.06

07158702

P3P2607CA1

480

9.03

07158902

F1F2610CA1

10

34130

208

1

48.07

24

26

1200

75

07159002

H1H2610CA1

240

41.66

07159102

G1G2610CA1

277

36.1

07159202

F3F2610CA1

208

3

27.79

07159302

H3H2610CA1

240

24.08

07159402

P3P2610CA1

480

12.04

07159602

F3F2615CA1

15

51195

208

41.68

24

39

1200

75

07159702

H3H2615CA1

240

36.12

07159802

P3P2615CA1

480

18.06

07160002

H3H2620CA1 19.4

68260

240

48.16

24

52

1200

75

07160102

P3P2620CA1

20

480

24.08

07175102

F3F2625CA1

25

85325

208

69.48

24

24

3300

175

07175202

H3H2625CA1

240

60.21

07175302

P3P2625CA1

480

30.1

07175502

F3F2630CA1

30 102390

208

83.37

29

3300

175

07175602

H3H2630CA1

240

72.25

07175702

P3P2630CA1

480

36.12

07175902

F3F2640CA1

40 136520

208

111.17

38

3300

175

07176002

H3H2640CA1

240

96.33

07176102

P3P2640CA1

480

48.16

07176302

F3F2650CA1

50 170650

208

138.96

48

3300

175

07176402

H3H2650CA1

240

120.42

07176502

P3P2650CA1

480

60.21