35

Optional controls must be factory installed. Field installation is not

acceptable and violates Listing and factory warranty.

Wall mounted control panels may control multiple units but cannot

be used if in-built controls are selected.

480V units include 24V transformer and relay as standard (A1) -

only TS option control section can be added. Depth dimension of all

480V models is 10-7/8”

Degree F air rise is measured at 710 F.P.M. and 425 CFM. Throw

designed for 8 to 12 foot ceilings. db RE 10

-12

Watt=63.9

Unit Weight:

50 lbs.

Recommended Remote Thermostats:

Line Voltage:

Single Phase 208-240V ET5DS

Single Phase 277V

ET5SS

Three Phase

TW1512

Low Voltage:

UT1001

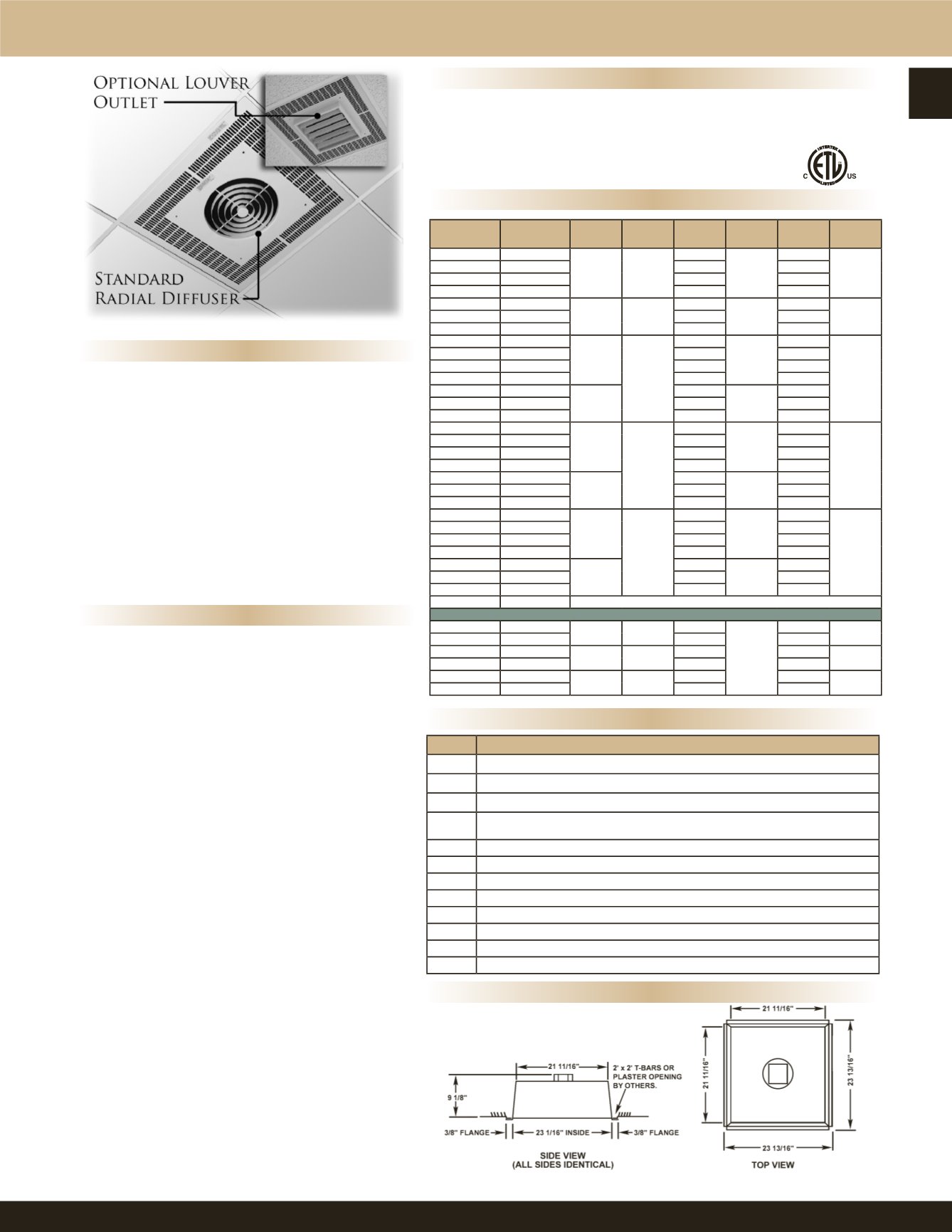

• White powder coated 20 gauge grill.

• 208V, 240V, & 277V units have manual reset thermal limit.

• 480V units have manual reset thermal limit, 24V control transformer,

and 24V relay (A1 suffix).

• Enclosed steel fin sheath element.

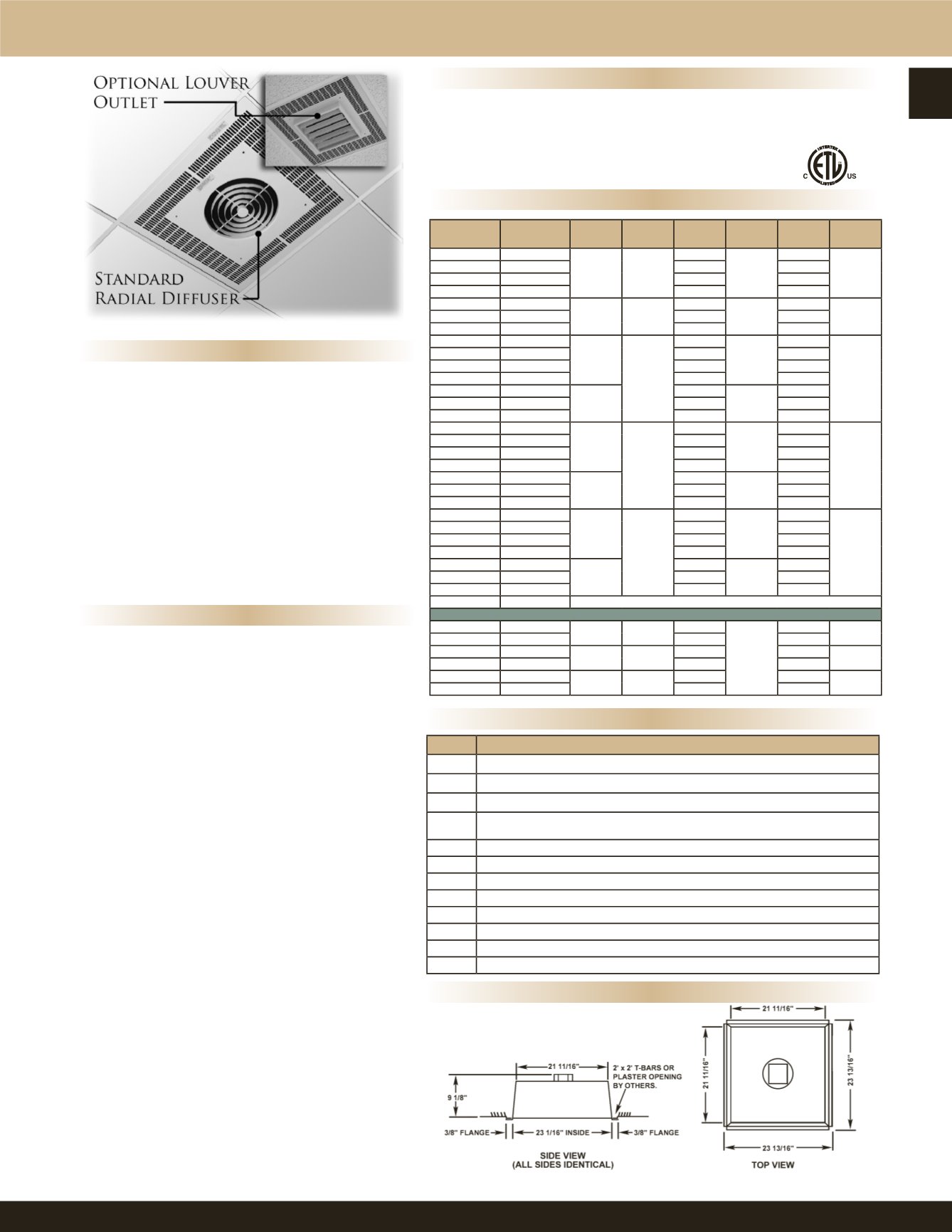

• Rough in dimensions: 23-1/16” sq. x 9-1/8” deep.

Notes

Standard Models

Product Dimensions

Product Specifications

Features

Factory Installed Control Sections

Contractor shall supply and install heavy duty ceiling mounted

forced air electric heater(s) of the wattage, voltage and phase as

indicated on the plans. The heater shall be so designed to provide an

even distribution of heated air to the space to be heated by drawing

return air in the periphery of the heater, across and through the

element and be discharged from the center section of the heater by

means of an electric motor and axial flow fan blade.

Heaters shall be recessed type and mounted flush with the finished

ceiling. The return grille assembly shall be constructed of a one

piece heavy gauge steel with 1/4” slots for return air and concentric

rings for uniform air discharge. Grille assembly shall be attached to

chassis by tamper-resistant (allen head) machine screws. All parts

of enclosure shall be heavy gauge steel, zinc coated both sides and

finished in neutral off white powder coat paint.

Enclosure shall be constructed of 1/6” x 3/8” rounded edge

horizontal steel louvers which shall be spaced for maximum opening

of 5/16”. Louvers shall be welded at every intersection to evenly

spaced 1/8” diameter vertical members. Discharge grille to have

concentric rings for uniform air discharge. Grille assembly shall be

attached to chassis by tamper-resistant (allen head) machine screws.

All part of enclosure shall be heavy gauge steel, Zinc coated both

sides and finished in neutral off white colored powder coat finish.

Motor shall be permanent lubricated, unit bearing, totally

enclosed, impedance protection. Motors shall operate at no more

than 1300 RPM and shall be same voltage as the heater.

Heaters shall have a rating of 425 CFM at 710 F.P.M. with a

maximum temperature rise of 44°F and 63.9 DB RE 10 12 Watt.

Element assemblies shall consist of two or three corrosion

resistant steel sheathed type elements mechanically bonded to

common corrosion resistant steel fins. Each sheathed element shall

consist of helically coiled Nickel Chromium alloy resistant wire

completely embedded in and surrounded by magnesium oxide,

enclosed and wedged into corrosion resistant steel sheaths. Elements

shall have 2” cold conductor pins extending into sheath and shall

have a density of no more than 60 Watts per inch.

Heaters shall be equipped with a “manual reset” thermal overload

which disconnects elements and motor in the event normal operating

temperatures are exceeded. For safety, if opened due to abnormal

temperature, thermal overload shall remain open until manually

reset. Automatic reset thermal overloads which allow the element

to continue to cycle under abnormal conditions will not be accepted.

Heaters shall be ETL listed.

Manufactured in U.S.A.

SUFFIX

DESCRIPTION

A1

Transformer with 24V Secondary and 24V Relay

S

Disconnect Switch

TA1S

Thermostat / Transformer / Disconnect Switch

TA1 Single Pole Thermostat and Transformer with 24V Secondary and 24V Relay

A1S Transformer with 24V Secondary and 24V Relay and Disconnect Switch

T2

Double Pole Thermostat

T2S

Double Pole Thermostat and Disconnect Switch

R

Relay Control Voltage Same as Heater (control voltage field supplied)

R1

Relay 24V Control Voltage (control voltage field supplied)

R2

Relay 120V Control Voltage (control voltage field supplied)

T

Single Pole (480V only)

L

Factory installed adjustable louver diffuser option.

3480 Series Commercial Fan Forced Recessed Mounted Ceiling Heater

UPC#

686344 MODEL KW BTU’S VOLTS PH AMPS TEMP

RISE

367653

F3482

2

6826

208

1

9.6

15 °F

367677

H3482

240

8.3

367660

G3482

277

7.2

318471 P3482A1

480

4.2

470186

J3482

2

6826

208

3

5.6

15 °F

470209

K3482

240

4.8

470247 Y3482A1

480

2.4

367684

F3483

3

10200

208

1

14.4

22 °F

367707

H3483

240

12.5

367691

G3483

277

10.8

318488 P3483A1

480

6.3

470193

J3483

3

208

3

8.3

470216

K3483

240

7.2

470254 Y3483A1

480

3.6

367714

F3484

4

13600

208

1

19.2

30 °F

367738

H3484

240

16.8

367721

G3484

277

14.4

318501 P3484A1

480

8.3

367745

J3484

4

208

3

11.1

367752

K3484

240

9.7

318587 Y3484A1

480

4.8

367769

F3485

5

17000

208

1

24.1

37 °F

367783

H3485

240

20.8

367776

G3485

277

18.1

318549 P3485A1

480

10.4

367790

J3485

5

208

3

13.9

367806

K3485

240

12.1

318402 Y3485A1

480

6.1

366106

PT3480

Recess Frame - Weight 5 lbs.

International Models

470971 M3482T2i

2

6826 220

1

9.1 15 °F

470988 N3482T2i

240

8.3

470995 M3483T2i

3

10200 220

13.6 22 °F

471008 N3483T2i

240

12.5

471015 M3484T2i

4

13600 220

18.2 30 °F

471022 N3484T2i

240

16.7